QUALITY

Working with Atus, you can be sure of the quality and reproducibility we will offer for every order. Why are we so confident? Because we are there at every stage of production, from the collection of material, through processing and storage to packaging. All of the production processes take place in our plants and are controlled by our team, and have been so for 20 years.

Full raw material control

We have our own supply chain, and our products are made only from high-quality recycled HDPE.

Careful material selection

Our raw materials are sorted using advanced optical machinery. Before the waste shredding stage, we remove all impurities and undesirable plastics to produce a high-quality material suitable for a wide range of production processes.

We constantly monitor our process

We have our own R&D department to conduct thorough quality tests, select optimum fraction parameters and remain flexible in our operations. This way, we can keep improving our processes to make products that meet the expectations of even the most demanding customers.

Quality by design

Every manufactured batch of material is comprehensively tested by our employees at various stages of the production process. This ensures that the product we supply always conforms to the specifications.

Our own laboratory and professional R&D

In Atus, innovation and responsibility take the form of specific actions, not just empty words. Our R&D team is working daily to improve the quality of our products, enhance our processes, and find solutions that will help us create materials that are more resistant, environmentally friendly and useful for society.

We perform the following quality tests:

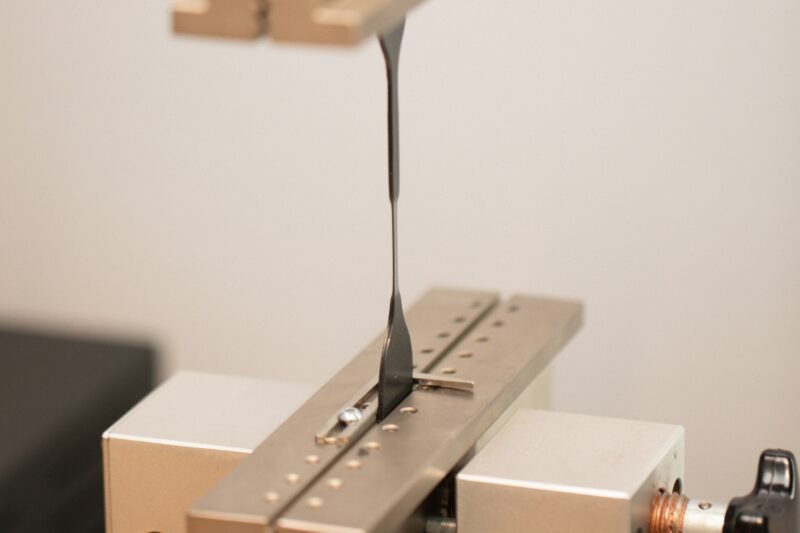

• Determination of mechanical properties

• Determination of puncture resistance

• Measurement of the melt flow index

• Oxidation induction time (OIT) testing

• Density measurement using the immersion method

• Determination of the grammage

• Determination of the carbon black content

• Joint strength testing

• Water leak tests

Certificates

Our products meet specified technical requirements and are environmentally friendly

EuCertPlast – European Certification of Plastics Recycling

EPD – Environmental Product Declaration

FPC Certificate of Conformity – Geosynthetic barriers for the construction of reservoirs and dams or channels; impermeable liquid barriers for the construction of tunnels and underground structures; for the construction of liquid waste sites, intermediate stations or secondary containment; for the construction of storage facilities and landfills for solid waste used in transport infrastructure

FPC Certificate of Conformity – Geotextiles and related products according to EN 13252

FPC Certificate of Conformity – Flexible waterproof products. Plastic and rubber products for dampproofing, including plastic and rubber products for the dampproofing of underground parts

National Technical Assessment – Pipes and fittings from polyethylene (PE) or polypropylene (PP) and casing pipes for systems or groundwater drainage

The Reach certificate – Regulation (EC) No 1907/2006 of the European Parliament and of the Council on safe use of chemicals by their registration and evaluation, and in some cases granting authorisations and restricting the marketing and use of certain dangerous substances